CPI China : Sustainable Cardboard Displays for Retail Marketing

Struggling to make your products stand out in a crowded retail space? Cardboard POP displays offer a cost-effective et eco-friendly option to elevate brand visibility while aligning with sustainability goals. This guide explores how custom cardboard displays from leading Chinese manufacturers combine high-impact visuals, adaptable designs, and logistical efficiency—from flat-pack shipping to innovative printing techniques—to transform retail merchandising strategies.

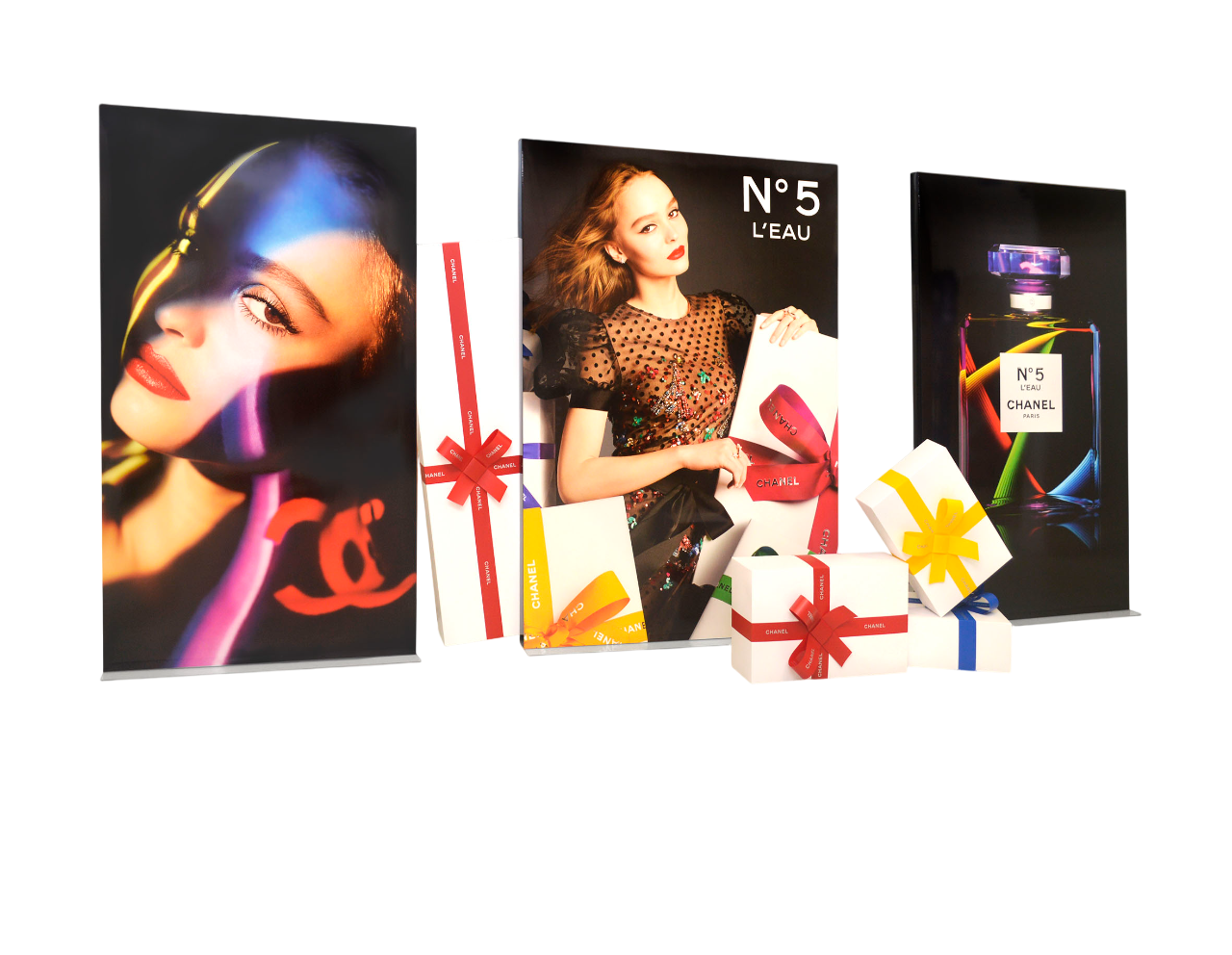

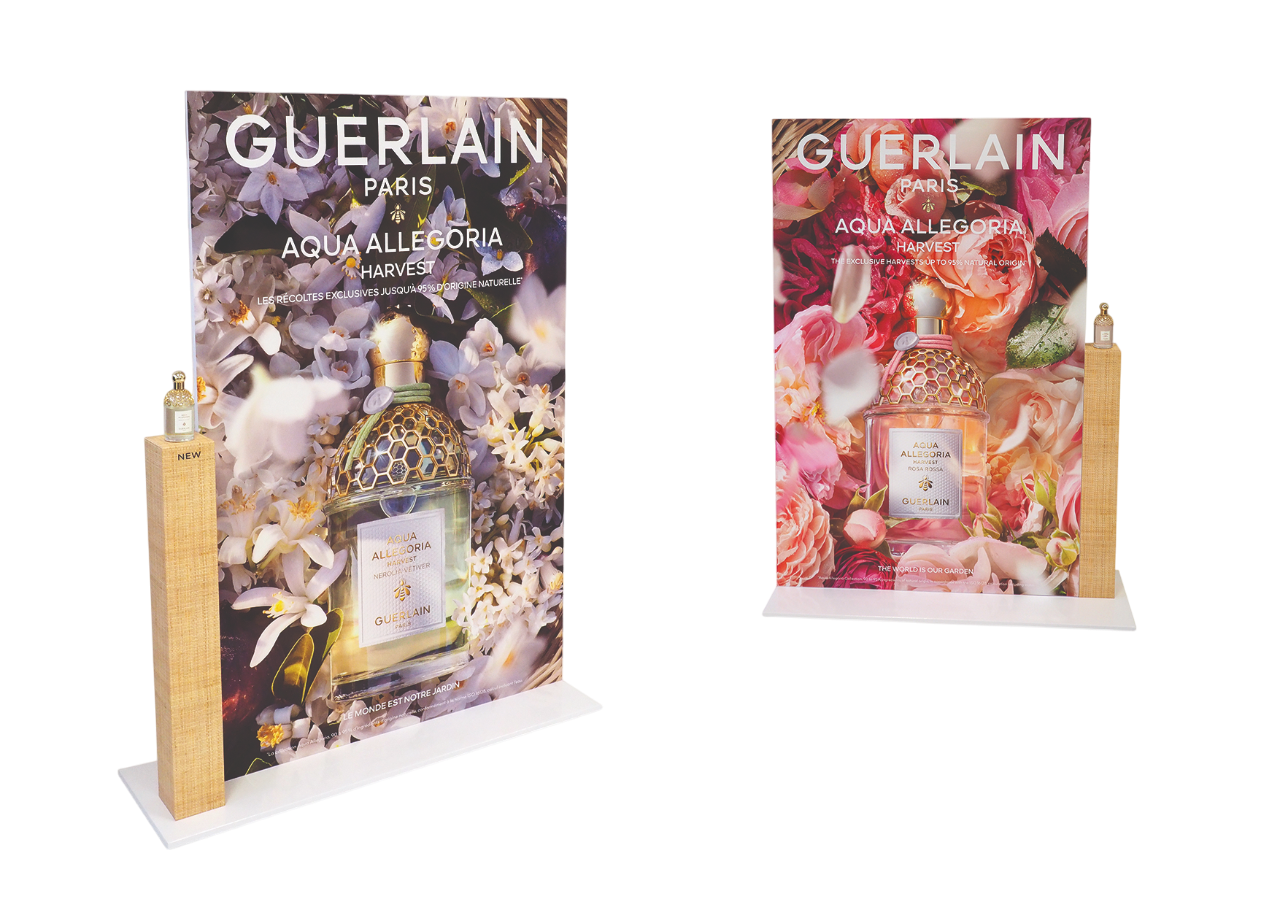

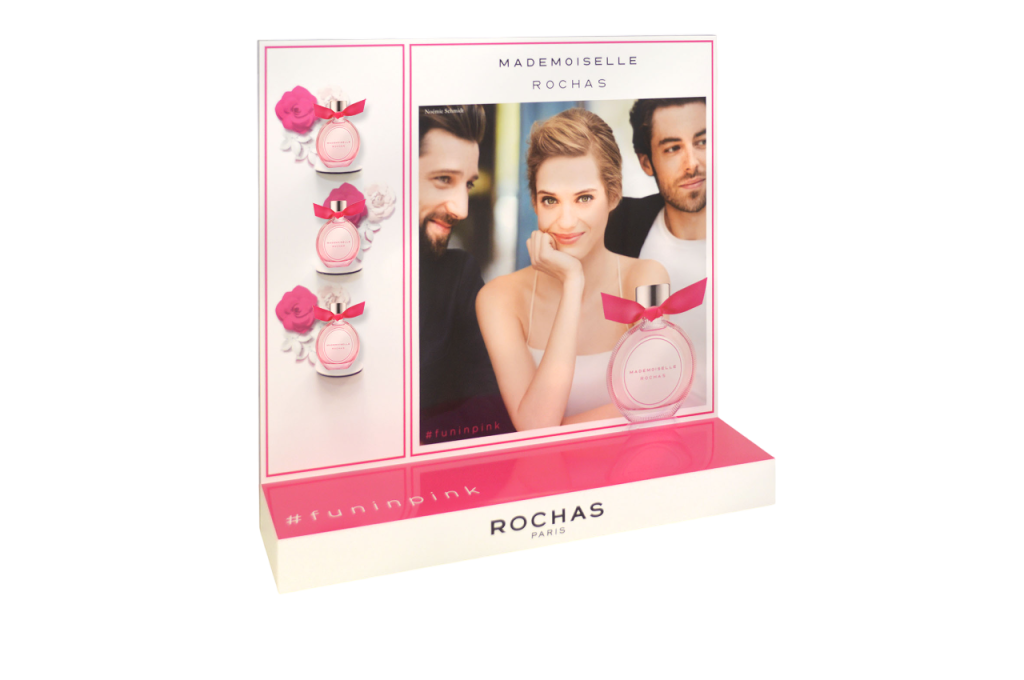

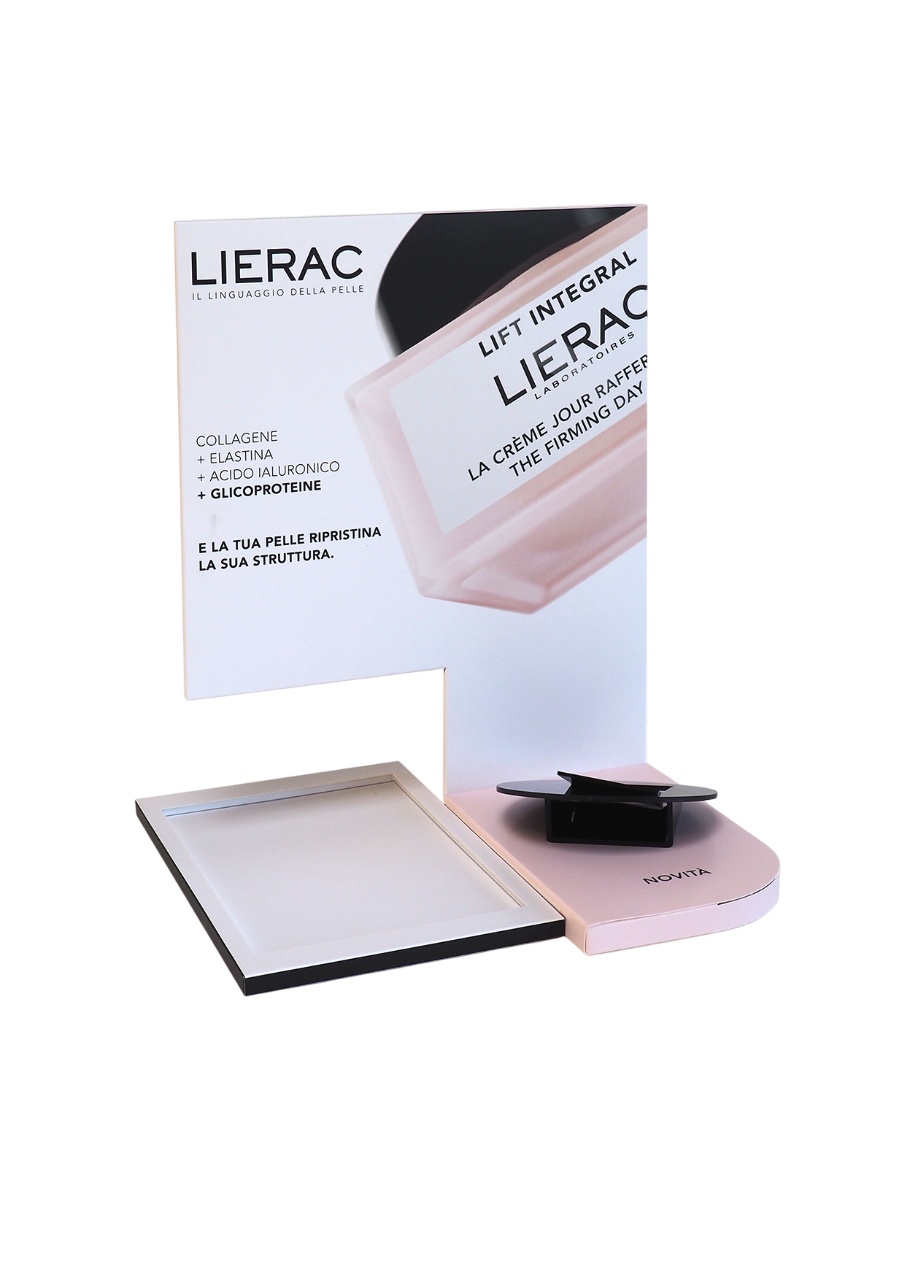

A LOOK AT OUR WORK

The Basics of Cardboard Displays in Modern Retail

Cardboard POP displays transform retail spaces through strategic product placement and brand storytelling. These corrugated displays combine cost-efficiency with high visual impact, offering floor stands, counter units, and pallet platforms. A 2020 study revealed a 56% surge in sustainably marketed goods, aligning with eco-conscious display solutions.

China’s cardboard display market features specialized manufacturers offering tailored retail solutions:

- Shenzhen WOW Packaging Display – 11+ years expertise in corrugated floor displays and countertop units with removable headers

- Leader Display – Custom-branded displays combining offset printing and structural engineering for shelf impact

- XMHJ Packaging – Eco-friendly tray displays using recycled cardboard and water-based inks

- HIC Display – Multi-tiered retail solutions integrating acrylic elements with corrugated structures

- Topwon Group – Flat-pack shipping designs with patented interlocking systems for global distribution

Corrugated displays outperform plastic alternatives through superior sustainability credentials – 100% recyclable with biodegradable options now comprising 38% of Chinese production. Lightweight construction cuts shipping costs by 20-30% versus traditional materials while maintaining structural integrity for product protection.

Prioritize floor displays for high-traffic zones and counter units for impulse purchases. Match display dimensions to product size while considering aisle width and shelf sightlines.

Customization and Manufacturing Strategies

Leading manufacturers combine digital printing techniques with structural engineering to create brand-specific displays. High-definition CMYK+White printing achieves 98% color accuracy on corrugated surfaces, while modular designs enable shelf displays with removable headers and adjustable product slots.

| ACE Display Solutions | 500 units 3-4 weeks | Custom floor displays with high-impact retail branding |

| Kontfeel Manufacturing | 100 units 2-3 weeks | Countertop displays and promotional brochure stands |

| LVH EcoDisplays | 1,000 units 4-5 weeks | Eco-friendly corrugated displays with removable headers |

| Créa PLV International | 500 units 2 weeks | Shelf displays and multi-tiered product presentation systems |

From cosmetics counters to electronics stores, cardboard displays adapt across sectors. FMCG brands utilize pallet displays for bulk promotions, while luxury goods employ counter units with velvet-lined trays. 78% of retail chains standardize displays across locations using modular systems.

Chinese factories now prevent 2.2 million tons of CO2 annually through recycled materials. Water-based adhesives and soy inks dominate 63% of production lines, with solar-powered facilities reducing energy consumption by 40% compared to conventional plants.

Logistics and Future Trends in Display Solutions

Flat-pack designs reduce shipping volumes by 60% through patented interlocking systems, enabling cost-effective global distribution. This approach cuts assembly time to under 15 minutes while preventing transit damage through component separation.

Emerging technologies are transforming cardboard POP displays:

- Augmented Reality Integration – QR-enabled displays triggering 3D product visualizations

- Smart Packaging Sensors – Corrugated displays with embedded NFC chips for inventory tracking

- Eco-Active Inks – Color-changing coatings indicating product freshness in food retail

- Modular Reconfigurable Systems – Interlocking units adapting to seasonal promotions

- Digital Printing Advancements – High-definition CMYK+White printing on recycled substrates

Bulk orders decrease costs by 40% through material optimization. Minimum order quantities balance inventory needs with budget constraints across retail tiers.

Strategic manufacturer partnerships ensure quality consistency across 98% of production runs. Leading suppliers now offer 5-year material warranties while maintaining ISO-certified sustainability standards for recycled content.

From versatile floor displays to sustainable corrugated solutions, cardboard POP units prove vital for boosting product visibility and brand impact. By partnering with trusted manufacturers, retailers unlock cost-effective customization while aligning with eco-conscious trends. As consumer expectations evolve, these adaptable displays remain strategic tools for staying competitive—today’s innovation becomes tomorrow’s retail advantage.